INNOVATION OF THE MONTH

INNOVATION OF THE MONTH

Reading time: 5 min

Rethinking processes: EVOPACK revolutionizes the preservation of water-based paint

Imagine you want to renovate your living room and you reach for the paint you bought a few years ago. You open the can of paint and are greeted by an unpleasant smell, indicating that the paint is spoiled. Disappointed, you realize that the paint has become unusable and you have to buy a new one to complete your project.

This scenario is familiar to many, but what if there was a solution? A solution that is not just for your personal use, but can also be used in larger applications such as business and industry.

This is where EVOPACK enters the picture, an innovative start-up from Stuttgart that has revolutionized the preservation of water-based paints. They have realized that conventional paint preservation is not in line anymore with today’s requirements for safety and health. Today’s alternative preservatives for paint often lead to undesirable results – such as smelly, spoiled paint – especially when opened once and stored.

In a world that increasingly demands sustainable action, innovations are needed that not only bring economic benefits but also make a positive contribution to the environment. EVOPACK, has done just that. They have taken up the challenge of completely rethinking the preservation of water-based paints and thus taking a significant step towards sustainability.

The inspiration for EVOPACK came from an unexpected angle. Instead of looking only within their own industry, they looked outside the box and found a source of inspiration in the food and pharma industry. There, similar challenges in terms of preservation and microbiology are already omnipresent. EVOPACK recognized the potential that arose from the sensitivity to natural and sustainable raw materials there, and made it their mission to transfer this knowledge to the paint industry.

What jam jars and paint cans have in common

The problem with fewer or weaker preservatives lies in the latent risk of microbial contamination. As soon as the conditions for microbial growth are met, microorganisms inevitably multiply. This not only leads to spoiled products, but also poses a potential health risk.

Perhaps you remember the last jam jar you dipped into? Spoon in, jam on the bread, quickly lick the rest off the spoon and realize you’re not quite full after all. Now what? Put the spoon back in the jar? If you feel like you’ve been caught out, don’t feel bad, you’re certainly not alone. So far, from a microbiological point of view, it’s not so bad – you’ve only brought in external bacteria. However, if you don’t put the jar back in the fridge or if you have chosen a jam made with too little sugar, which acts as a preservative, then you will see a germ infestation with the naked eye after a few days. Exactly the same thing happens with many water-based paints nowadays. Open the pot, put the brush in, put the brush on the wall (which is not sterile), put the brush back in, close the pot and put it on the shelf.

EVOPACK’s answer to the challenges of the industry

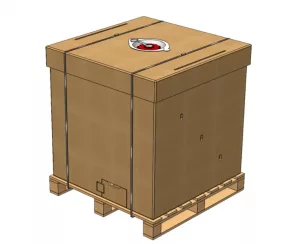

EVOPACK recognized this challenge and developed innovative solutions that are not only effective, but also sustainable and environmentally conscious. Concepts such as the „Boxli1000“ are a great alternative to the traditional IBC (Industrial Bulk Container). Boxli1000 is based on a so-called bag-in-box packaging technology (you might know this from 5L apple juice packaging). The trick to avoid preservatives with flexible packaging is that the packaging is in perfect contact with the liquid in any filling stage and does not allow air to go inside. In this way EVOPACK can ensure that no contamination goes into the product until the last drop leaves the packging. Further, this innovative packaging is made from 90% recyclable, non-fossil raw materials and can also be 95% reused and recycled!

Shifting paradigms

In the food industry, packaging plays a decisive role in the sustainability of products. So why shouldn’t this also work in the paint industry? By reducing packaging material and using recyclable raw materials, EVOPACK makes an important contribution to environmental protection.

The biggest challenge for EVOPACK was not only the development of new products, but also their acceptance and integration into existing industrial processes. Many plants and production facilities were built decades ago and did not take into account the requirements for preservative-free products. Nevertheless, EVOPACK firmly believes that clean processes are possible even with existing infrastructure – provided there is a clear commitment to quality assurance and process optimization.

Reaching the goal together

The aim is to make preservative-free paint available on the market for end consumers by 2025. EVOPACK still has a long way to go until then, but with a lot of support from industry partners, EVOPACK’s founders are optimistic.

“So far, we have received a lot of positive support from the “big sharks” and more helping hands than headwinds. At the end of the day, it’s only people who work there, and most of them would rather contribute to the buffet than add salt to it. The more people who help to offer such solutions, the better it is for all of us.”

In a world that demands sustainable action more than ever, the connection to projects like EVOPACK is also crucial for prototype.club. We firmly believe that innovation and collaboration are key to a sustainable future. As an advocate of open innovation and a partner for start-ups, we provide a platform to support pioneering ideas like EVOPACK. Together, we are not only reshaping the industry, but also doing our part to preserve our environment for ourselves and future generations.